Flat Metal Rolling Leveler

Metal Side Trimming/Shearing Machine

Coil Coaters

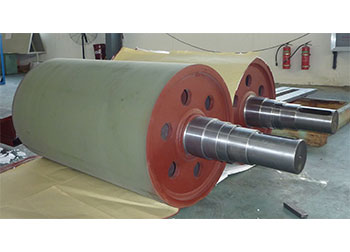

Spare Parts

Flat Metal Finishing Line

Fine Blanking

Revamping and Repair

Company Profile

Company Culture

Honor Certificates

Factory Show

Quality Control

Our History

Social Responsibility

Search

English

English