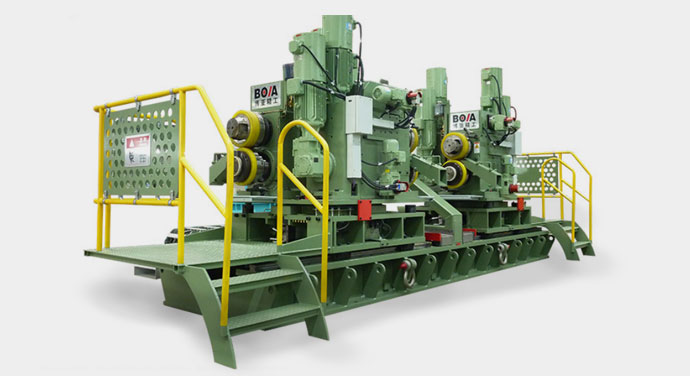

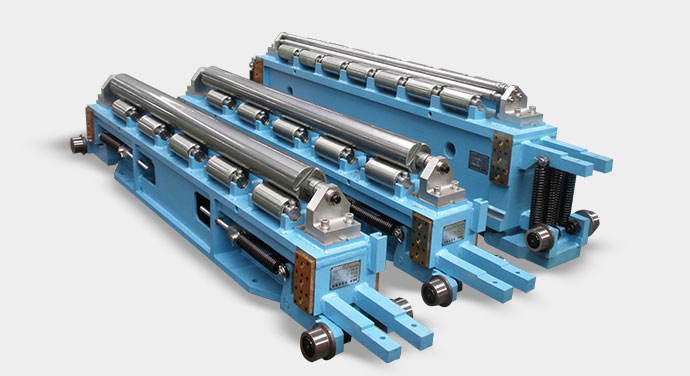

After years of professional research and development, BOYA is committed to providing high-quality metal processing equipment. Our metal processing machinery is not only rooted in the basic theory of material elastoplastic deformation, but also actively innovates in combination with processing materials. Our metal processing machinery can handle materials-from coils to plates, in order to provide full preparation for downstream processing. In addition, it is worth mentioning that our metal processing machinery can ensure that flat materials have low internal stress. BOYA, one of the reliable metal processing machinery manufacturers, is committed to contributing its own strength to improve the quality of your parts!

Innovative Solutions for Every Challenge: Your Trusted Metal Processing Machinery Manufacturer

▶ R&D investment: We invest a lot of resources into the R&D department every year to ensure that our metal processing machines are always at the forefront of the industry.

▶ Customer feedback: Through close cooperation with global customers, we continuously collect and analyze feedback from actual use, quickly iterate and improve metal processing equipment.

▶ Advanced technology: We have introduced the latest automation and intelligent manufacturing technologies to make metal processing machinery more efficient, precise and reliable.

▶ Professional team: Boya company's R&D team is composed of top engineers and technical experts in the industry, who are constantly exploring new solutions and technological breakthroughs.

▶ Global vision: We actively participate in international exhibitions and technical exchanges, absorb advanced concepts and technologies worldwide, and ensure that our metal processing machine is always internationally competitive.

English

English